Hardwood Photos and Descriptions (alphabetical)

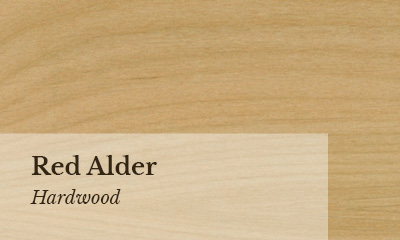

(Alnus rubra // Origin-Western North America) Red alder is almost white when freshly cut but quickly changes on exposure to air to light brown with a yellow or reddish tinge. Heartwood is formed only in trees of advanced age and there is no visible boundary between sap and heartwood. The wood is fairly straight grained with a uniform texture.

Uses: Furniture, kitchen cabinets, doors, interior mouldings, turning, carving and kitchen utensils.

Wood Working Properties: Red alder machines well and is excellent for turning and polishing. It nails, screws and glues well, and can be sanded, painted, or stained to a good finish. Red alder is a relatively soft hardwood of medium density that has low bending strength, shock resistance and stiffness. It dries easily with little degrade and has good dimensional stability after drying.

(Faxinus Americana// Origin-US) Grows in Eastern North America from the Mississippi river valley to the Atlantic coast Ash sapwood is light-colored to nearly white and the heartwood varies from grayish or light brown, to pale yellow streaked wit brown. Ash is generally straight-grained with a coarse uniform texture. The main uses are furtinure, flooring, doors, architectural millwork and moulding and kitchen cabinets. Grows in Eastern North America from the Mississippi river valley to the Atlantic coast.

Uses: Furniture, flooring, doors, architectural interiors, high class joinery and moulding, kitchen cabinets, paneling, tool handles, sports goods and turning.

Wood Working Properties: Heavy and hard wood with good dimensional stability and minimal shrinkage; No natural resistance to decay. Easy to work, cuts, planes, nails and bends well; not recommended for turning or mortising; good staining properties.

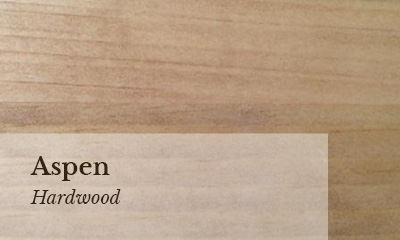

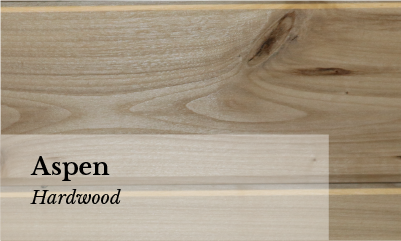

(Populus tremuloides //Origin –US & Canada) Common to the American West. Sapwood is white, blending into the light brown heartwood. The contrast between sap and heartwood is small. The wood has a fine uniform texture and is straight grained.

Uses: Furniture parts (drawer sides), doors, mouldings, picture frames, interior joinery, toys, kitchen utensils. Matchsticks (USA). Important specialized uses include sauna laths because of its low conductivity of heat, and chopsticks.

Wood Working Properties: The wood is light and soft, with low bending strength and stiffness, and medium shock resistance. It has very low bending classification. Very soft wood fuzzes when sanded but does work well with tools. Low fastening strength and fairly high flame resistance.

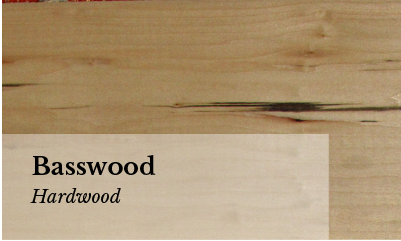

(Tilia americanan // Origin US & Canada) The sapwood of basswood is usually quite large and creamy white in color, merging into the heartwood which is pale to reddish brown, sometimes with darker streaks. The wood has a fine uniform texture and indistinct grain that is straight.

Uses: Carving, turning, furniture, pattern-making, mouldings, interior joinery and musical instruments. An important specialized use is Venetian blinds.

Wood Working Properties: Basswood machines well and is easy to work with hand tools making it a premier carving wood. It nails, screws, and glues fairly well and can be sanded, stained, and polished to a good smooth finish. It dries fairly rapidly with little distortion or degrade. It has a fairly large shrinkage but good dimensional stability when dry.

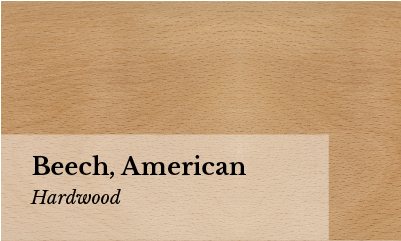

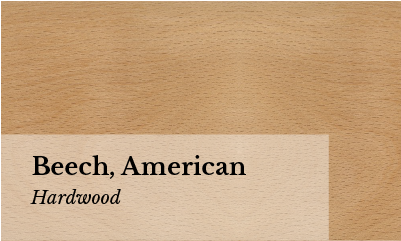

(Fagus grandifolia //Origin- Eastern United States) Beech is typically a pale cream color, sometimes with a pink or brown hue. Veneer tends to be slightly darker colored, as slicing the veneer usually requires the wood to be prepared with steam, which gives the wood a more golden tone. Flatsawn surfaces tend to be very plain, while quarter sawn surfaces exhibit a silvery fleck pattern.

Uses: Lumber, veneer, flooring, crates/pallets, railroad ties, musical instruments, furniture, turned objects, and other small wooden objects.

Wood Working Properties: Overall good workability; it machines well, and glues, finishes, and turns well. Beech also responds superbly to steam-bending. It does, however, have a large amount of movement in service, so movement and wood stability must be taken into account.

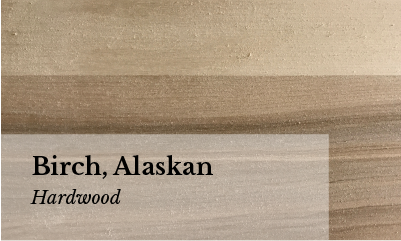

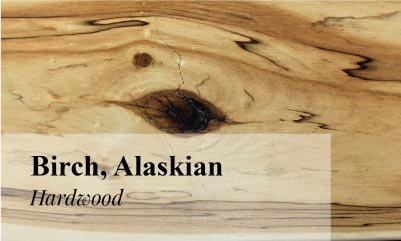

(Betula neoalaskana // Origin Alaska & Northern Canada) Heartwood tends to be a light reddish brown, with nearly white sapwood. Occasionally figured pieces are available with a wide, shallow curl similar to the curl found in Cherry. There is virtually no color distinction between annual growth rings, giving Birch a somewhat plain, uniform appearance.

Uses: Plywood, boxes, crates, turned objects, interior trim, and other small specialty wood items. Birch is one of the most widely used woods for veneer and plywood worldwide. Besides regular sheets of plywood, Birch veneer is also used for doors, furniture, and paneling.

Wood Working Properties: Generally easy to work with hand and machine tools, though boards with wild grain can cause grain tear-out during machining operations. Turns, glues, and finishes well.

Spalting is any form of wood coloration caused by fungi. Although primarily found in dead trees, spalting can also occur in living trees under stress. Although spalting can cause weight loss and strength loss in the wood, the unique coloration and patterns of spalted wood are sought by woodworkers. Spalting is caused by certain white-rot decay fungi growing in wood–primarily hardwoods such as maple, birch, and beech. … The unusual coloration–black, pink, gray, and multicolored streaks–may result from reactions between the wood, the decay fungi, and insect deposits.

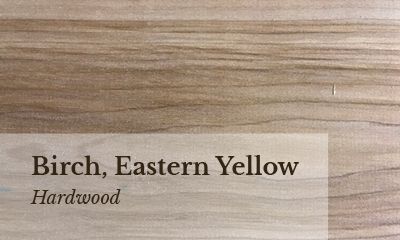

(Betula alleghaniensis // Origin- Northeastern North America) Heartwood tends to be a light reddish brown, with nearly white sapwood. The wood is generally straight grained with fine uniform texture. There is virtually no color distinction between annual growth rings, giving Birch a somewhat plain, uniform appearance.

Uses: Furniture, millwork and paneling, doors, flooring, kitchen cabinets, turnings and toys.

Wood Working Properties: The wood works fairly easily, glues well with care, takes stain and polish extremely well, and nails and screws satisfactorily where pre-boring is advised. The wood of yellow birch is heavy, hard and strong. It has very good wood bending properties, with good crushing strength and shock resistance. It dries rather slowly with little degrade, but it has moderately high shrinkage, so is susceptible to movement in performance.

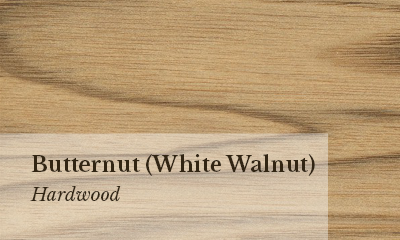

(Juglans cinerea // Origin-Eastern United States) Heartwood is usually a light to medium tan, sometimes with a reddish tint. Growth rings are darker and form fairly distinct grain patterns. Sapwood is pale yellowish white.

Uses: Veneer, carving, furniture, interior trim, boxes, and crates.

Wood Working Properties: Butternut is easily worked with both hand and machine tools. However, being so soft, Butternut has a tendency to leave some fuzzy surfaces after planning or sanding, and sharp cutters and fine-grit sandpaper is recommended. Butternut glues, stains, and finishes well.

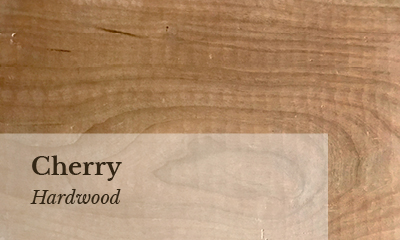

(Prunus serotina // Origin- US) The heartwood of cherry varies from rich red to reddish brown and will darken on exposure to light. In contrast, the sapwood is creamy white. The wood has a fine uniform straight grain, smooth texture, and may naturally contain brown pith flecks and small gum pockets.

Uses: Furniture and cabinet making, high class joinery, kitchen cabinets, mouldings, paneling, flooring, doors, boat interiors, musical instruments, turning and carving.

Wood Working Properties: Cherry is easy to machine, nails and glues well and when sanded, stained and polished, it produces an excellent smooth finish. The wood is of medium density with good wood bending properties; it has low stiffness and medium strength and shock resistance. It must dry slowly to avoid warping, but dries fairly quickly with moderately large shrinkage, but is dimensionally stable after kilning.

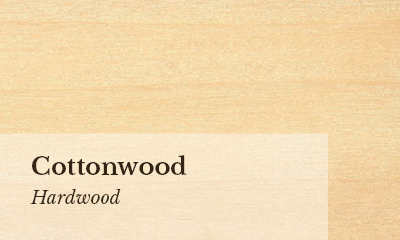

(Populus deltoidus // Origin-Eastern US) The sapwood is white and may contain brown streaks while the heartwood may be pale to light brown. It is a diffuse porous timber with a coarse texture. The wood is generally straight grained and contains relatively few defects. Cottonwood is a true poplar, and therefore has similar characteristics and properties to aspen and European poplar.

Uses: Furniture, furniture parts, interior joinery and mouldings, toys and kitchen utensils. A specialized use (USA) is Venetian blinds, shutters, and caskets.

Wood Working Properties: General machinability is fair, although tension wood is frequently present and can cause a fuzzy surface when cut, which in turn will require additional care when finishing. The wood glues well and has good resistance to splitting when nailing and screwing. It dries easily but may still have a tendency to warp, with small movement in performance.

(Carya spp. // Origin- Eastern US) Hickory is the hardest, heaviest and strongest American wood. The hickories are an important group within the Eastern hardwood forests. Botanically they are split into two groups; the true hickories, and the pecan hickories (fruit bearing). The sapwood of hickory is white, tinged with inconspicuous fine brown lines while the heartwood is pale to reddish brown. Both are coarse-textured and the grain is fine, usually straight but can be wavy or irregular. The wood is virtually the same for both and is usually sold together.

Wood Working Properties: The hickories are considered difficult to machine and glue, and are very hard to work with hand tools, so care is needed. The density and strength of the hickories will vary according to the rate of growth, with the true hickories generally showing higher values than the pecan hickories. The wood is well known for its very good strength and shock resistance and it also has excellent steam bending properties.

They hold nails and screws well, but there is a tendency to split so pre-boring is advised. The wood can be sanded and polished to a good finish. It can be difficult to dry and has a large shrinkage.

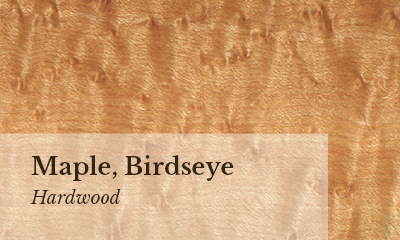

Birdseye Maple is not technically a distinct species of Maple, but rather, it’s a figure that’s occasionally found in Acer saccharum (Sugar Maple) trees. It’s named “birdseye” (sometimes simply written out as Bird’s Eye Maple) because the figure resembles small bird’s eyes. The figure is reportedly caused by unfavorable growing conditions for the tree. The Sugar Maple attempts to start numerous new buds to get more sunlight, but with poor growing conditions the new shoots are aborted, and afterward a number of tiny knots remain.

Birdseye Maple is frequently sold in veneer form, but solid lumber is available as well. Being tiny knots, the birdseye figure is most noticeable and pronounced on flatsawn pieces of lumber.

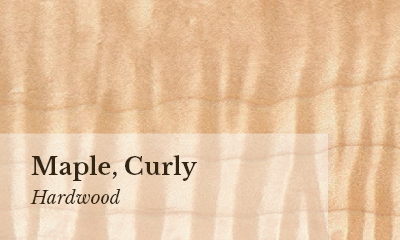

Curly Maple is not actually a species, but simply a description of a figure in the grain—it occurs most often in soft maples, but is also seen in hard maples. It is so called because the ripples in the grain pattern create a three dimensional effect that appears as if the grain has “curled” along the length of the board. Other names for this phenomenon are: tiger maple, fiddle-back maple, (in reference to curly maple’s historic use for the backs and sides of violins), or flamed maple. Unlike quilted maple, curly maple is most pronounced when the board is quarter sawn, and the curls usually become much less pronounced or absent in flatsawn boards. Hence, on wide boards where the grain tends to be close to vertical (quarter sawn) near the edges and horizontal (flatsawn) in the center, the curly pattern will be most evident on the edges of the board, with the figure diminishing in the center. It is not completely clear what environmental conditions (if any) cause this phenomenon, but there are different grades of curly maple, which greatly affect its price. Ideally, the criteria for determining value is based upon: color (both uniformity and lightness—whiter is preferred), frequency of the curls (tight, closely-spaced curls are preferred), and intensity (more depth is preferred). Prices can range from just slightly more expensive than regular soft maple for lower grades of curly maple, to triple, quadruple, or higher for prices of the highest grades. But in general, higher grades of curly maple tend to be less expensive than quilted maple, and offer an economical solution for a “figured” hardwood.

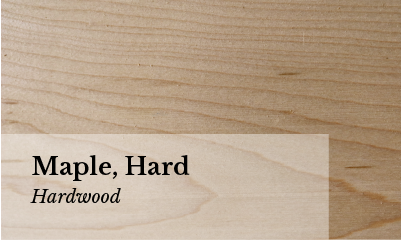

(Acer saccharum, A. nigrum // Origin- Eastern U.S., principally Mid-Atlantic and Lake states) Hard Maple typically refers to one specific type of maple species: Acer saccharum; also known as Rock Maple or Sugar Maple, (this is the same tree which is tapped to get maple syrup). The sapwood is creamy white with a slight reddish brown tinge and the heartwood varies from light to dark reddish brown. The amount of darker brown heartwood can vary significantly according to growing region. Both sapwood and heartwood can contain pith fleck. The wood has a close fine texture and is generally straight grained, but it can also occur as ‘curly’, ‘fiddleback’, and ‘birds-eye’ figure.

Uses: Flooring, furniture, paneling, ballroom and gymnasium floors, kitchen cabinets, worktops, table tops, butchers blocks, toys, kitchenware and millwork: stairs, handrails, mouldings, and doors.

Wood Working Properties: The wood is hard and heavy with good strength properties, in particular its high resistance to abrasion and wear. It also has good steam-bending properties.

Hard maple dries slowly with high shrinkage, so it can be susceptible to movement in performance. Pre-boring is recommended when nailing and screwing. With care it machines well, turns well, glues satisfactorily, and can be stained to an outstanding finish. Maple polishes well and is suitable for enamel finishes and brown tones.

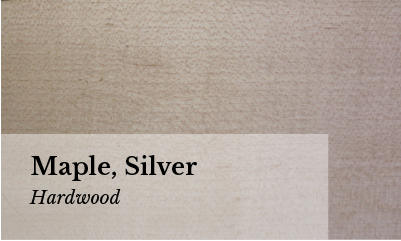

(Acer saccharinum // Origin- Northeastern United States) Unlike most other hardwoods, the sapwood of maple lumber is most commonly used rather than its heartwood. Sapwood color ranges from almost white, to a light golden reddish brown, while the heartwood is a darker reddish brown. Silver Maple can also be seen with curly or quilted grain patterns.

Uses: Veneer, paper (pulpwood), boxes, crates/pallets, musical instruments, turned objects, and other small specialty wood items.

Wood Working Properties: Fairly easy to work with both hand and machine tools, though maple has a tendency to burn when being machined with high-speed cutters such as router. Turns, glues and finishes well, though blotches can occur when staining, and a pre-conditioner, gel stain, or toner may be necessary to get an even color.

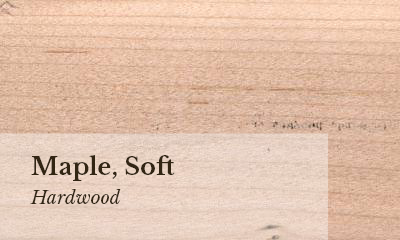

(Principally Acer rubrum, A. saccharinum // Origin- Eastern & West Coast US) First of all, the term “Soft Maple” does not refer to any specific species of maple, but rather, it’s a broad term, which includes several different species of maple. The term “Soft Maple” is merely used to differentiate these species from Hard Maple. Some of the most common species of maple that fall under the grouping of Soft Maple are: Big Leaf Maple, Boxed Elder, Red Maple, Silver Maple, Striped Maple. In most respects the wood of soft maple is very similar to that of hard maple. Although due to its widespread growth it may be more susceptible to regional colour variations. Generally the sapwood is greyish white, sometimes with darker coloured pith flecks. The heartwood varies from light to dark reddish brown. The wood is usually straight grained. The lumber is generally sold unselected for colour.

Uses: Furniture, panelling, interior joinery, kitchen cabinets, mouldings, doors, musical instruments, and turning. Soft maple is often used as a substitute for hard maple or stained to resemble other species such as cherry. Its physical and working properties also make it a possible substitute for beech.

Wood Working Properties: Soft maple machines well and can be stained and polished to an excellent finish. It glues, screws, and nails satisfactorily. It dries slowly with minimal degrade and there is little movement in performance.

(Quercus spp. // Origin- Eastern US) The sapwood of red oak is white to light brown and the heartwood is a pinkish reddish brown. The wood is similar in general appearance to white oak, but with a slightly less pronounced figure due to the smaller rays. The wood is mostly straight-grained, with a coarse texture.

Uses: Furniture, flooring, architectural millwork and mouldings, doors, kitchen cabinets, paneling and caskets.

Wood Working Properties: The wood is hard and heavy, with medium bending strength and stiffness and high crushing strength. It is very good for steam bending. Great wear-resistance. Red oak machines well, nailing and screwing are good although pre-boring is recommended, and it can be stained to a good finish. It can be stained with a wide range of finish tones. It dries slowly.

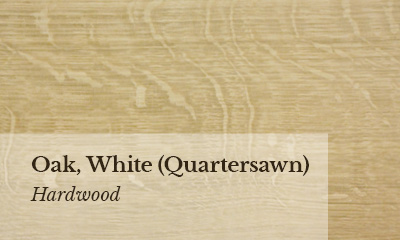

(Quercus spp // Origin- Eastern US) The sapwood is light-colored and the heartwood is light to dark brown. White oak is mostly straight-grained with a medium to coarse texture, with longer rays than red oak. White oak therefore has more figure. The white oak group comprises many species, of which about eight are commercial.

Uses: Furniture, flooring, architectural millwork, mouldings, doors, kitchen cabinets, paneling, barrel staves (tight cooperage) and caskets. White Oak is also good for truck decking (lighter and typically cheaper than Apitong).

Wood Working Properties: A hard and heavy wood with medium bending and crushing strength, low in stiffness, but very well in steam bending. Great wear-resistance. White oak machines well, nails and screws well although pre-boring is advised. Since it reacts with iron, galvanized nails are recommended. Its adhesive properties are variable, but it stains to a good finish. Can be stained with a wide range of finish tones. The wood dries slowly.

White Oak has a medium to coarse texture, with longer rays than red oak. White oak therefore has more figure. Plain sawn (or flat sawn) lumber has the growth rings of the tree approximately perpendicular to the boards surface and has the straightest grain. Quarter sawn lumber has the growth rings of the tree parallel to the board’s broad face. Quarter sawn wood highlights the grain, loops and growth swirls of the wood. The grain of Quarter Sawn White Oak includes decorative effects such as ray flecks, interlocking, and wavy “ribbon” patterns, which are often featured in fine furniture and cabinetry.

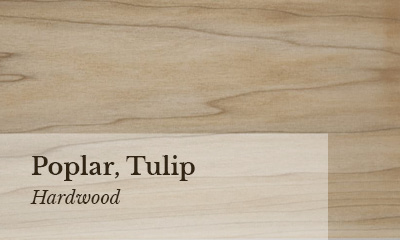

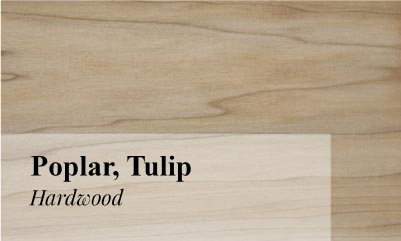

(Liriodendron tulipifera – Other Names: Yellow Poplar, Tulip Wood // Origin- Eastern US) The sapwood is creamy white and may be streaked, with the heartwood varying from pale yellowish brown to olive green. The green color in the heartwood will tend to darken on exposure to light and turn brown. The wood has a medium to fine texture and is straight-grained; has a comparatively uniform texture.

Uses: Light construction, furniture, kitchen cabinets, doors, musical instruments, exterior trim and siding, paneling, mouldings and millwork, edge-glued panels, turnings and carvings.

Wood Working Properties: A medium density wood with low bending, shock resistance, stiffness and compression values, with a medium steam-bending classification; Excellent strength and stability. A versatile wood that is easy to machine, plane, turn, glue and bore. It dries easily with minimal movement in performance and has little tendency to split when nailed. It takes and holds paint, enamel and stain exceptionally well.

(Alnus rubra // Origin-Western North America) Red alder is almost white when freshly cut but quickly changes on exposure to air to light brown with a yellow or reddish tinge. Heartwood is formed only in trees of advanced age and there is no visible boundary between sap and heartwood. The wood is fairly straight grained with a uniform texture.

Uses: Furniture, kitchen cabinets, doors, interior mouldings, turning, carving and kitchen utensils.

Wood Working Properties: Red alder machines well and is excellent for turning and polishing. It nails, screws and glues well, and can be sanded, painted, or stained to a good finish. Red alder is a relatively soft hardwood of medium density that has low bending strength, shock resistance and stiffness. It dries easily with little degrade and has good dimensional stability after drying.

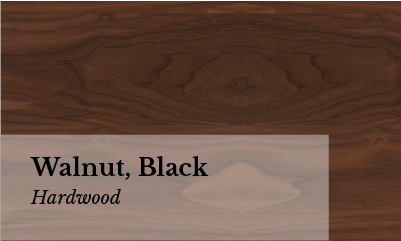

(Juglans nigra //Origin- US) The sapwood of walnut is creamy white, while the heartwood is light brown to dark chocolate brown, occasionally with a purplish cast and darker streaks. Walnut can be supplied steamed, to darken sapwood or left un-steamed. The wood is generally straight grained, but sometimes with wavy or curly grain that produces an attractive and decorative figure. Grows in Eastern North American and the Northwestern portion of South America.

Uses: Furniture, cabinet making, architectural interiors, high class joinery, doors, flooring, and paneling. A favored wood for using in contrast with lighter colored timbers.

Wood Working Properties: Walnut works easily with hand and machine tools, and nails, screws and glues well. It holds paint and stain very well and can be polished to an exceptional finish. It dries slowly, and care is needed to avoid kilning degrade. Walnut has good dimensional stability.